ADVANCED THERMAL RUNAWAY PACKAGING FOR LITHIUM BATTERIES

Lithium batteries are used in a wide range of applications and have become increasingly popular due to their high energy density and long lifespan. However, it’s important to note that while lithium batteries are generally safe when used properly, they do carry some risks, including the potential for thermal runaway.

Thermal runaway is a phenomenon that can occur when a lithium battery experiences an uncontrolled increase in temperature, leading to a self-sustaining and uncontrollable reaction. This can result in a rapid release of heat, gas, and sometimes even flames. It’s a serious concern because traditional fire suppression methods may not be effective in extinguishing a lithium battery fire.

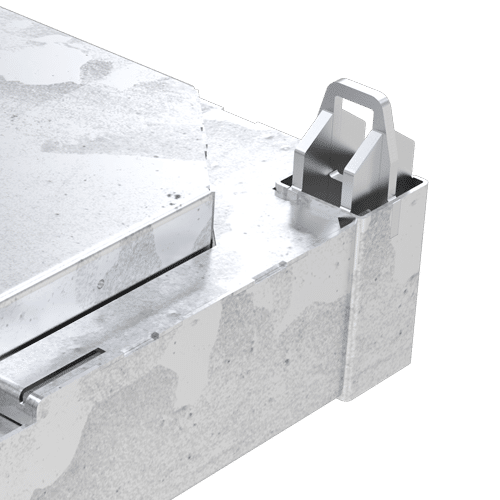

Given the potential hazards associated with lithium batteries, it is crucial to have safe and certified packaging for transportation, storage, and handling. BUNCKER® has designed a patented packaging solution to mitigate the risks and provide protection in case of thermal runaway or other incidents. Its patented fire resistance, insulation, and filtering material, known as “Altilium,” and mechanisms to contain and vent gases in a controlled manner aim to contain thermal runaway incidents that can occur in lithium batteries. By offering protection for both stable and unstable lithium batteries, BUNCKER® provides a versatile solution.

Several organizations and regulatory bodies have established international guidelines and standards for the safe transport, storage, and handling of lithium batteries. These standards address packaging requirements, labelling, documentation, and other aspects to ensure the safe handling and transportation of lithium batteries.

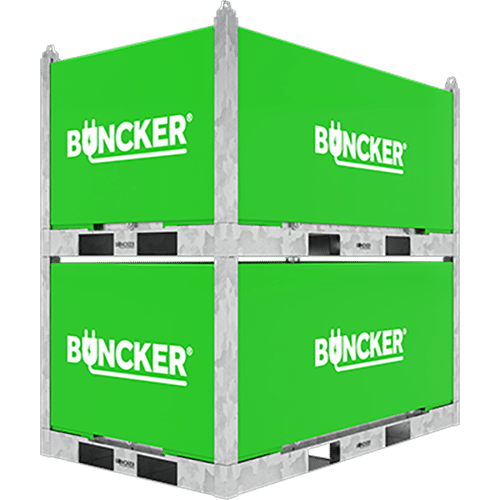

Forklift all sides and lifting possibility

Less spacing, storage and transport

Palletfoot standard, bel jar design and one-man handling

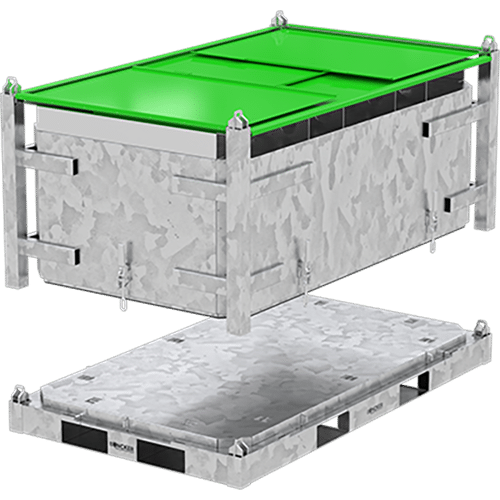

Non-combustible and no need for filling material

Fixation of batteries with straps and centering points on the palletfoot

Easy and quick way of closing

| Buncker® Pro Line Heavy assortment | S | M | L | XL | XXL |

| Outer dimensions (mm) | 1200 x 1000 x 1150 | 1500 x 1200 x 1250 | 2000 x 1200 x 950 | 2400 x 1200 x 950 | 2800 x 2000 x 950 |

| Product space dimensions | 920 x 720 x 750 | 1220 x 920 x 850 | 1720 x 920 x 550 | 2120 x 920 x 550 | 2520 x 1720 x 550 |

| Empty weight per pallet box in kgs | 365 | 508 | 536 | 621 | 1120 |

| Number of closures | 6 | 6 | 6 | 8 | 10 |

| Max. capacity nett weight of batteries in kgs | 435 | 700 | 700 | 800 | 1540 |

| Max. capacity of lithium batteries in kWh | 50 | 90 | 90 | 100 | 200 |

Product delivery is inclusive straps & non-conductive mat

The UN certification is an important aspect of BUNCKER®, as it indicates that the packaging meets the safety standards set by the United Nations for transport of Dangerous Goods. This certification ensures that the product has passed a worst-case scenario fire testing, leak testing and drop testing and evaluation to ensure its effectiveness in containing and preventing hazards associated with lithium batteries. The tests and evaluation proofs that BUNCKER® can contain a thermal runaway.

Be aware that when there is a need for packaging for defected or damaged batteries, an UN approval based on drop & stacking tests is not adequate nor sufficient. To ship in accordance with P911/LP906 an additional certification is needed, with an approval that confirms that the packaging has:

all based on a mentioned maximum tested kWh’s of lithium batteries.

Therefor always request for the UN test report and additional P911/LP906 certification that confirms the approved way of the packing instruction how to secure the batteries against displacement, how to make the box fire resistant and the limits of usage in Kgs and kWh for Road (ADR), Rail (RID) and Sea (IMDG) transport.

A copy of these certificates should be attached to the packaging during transport.

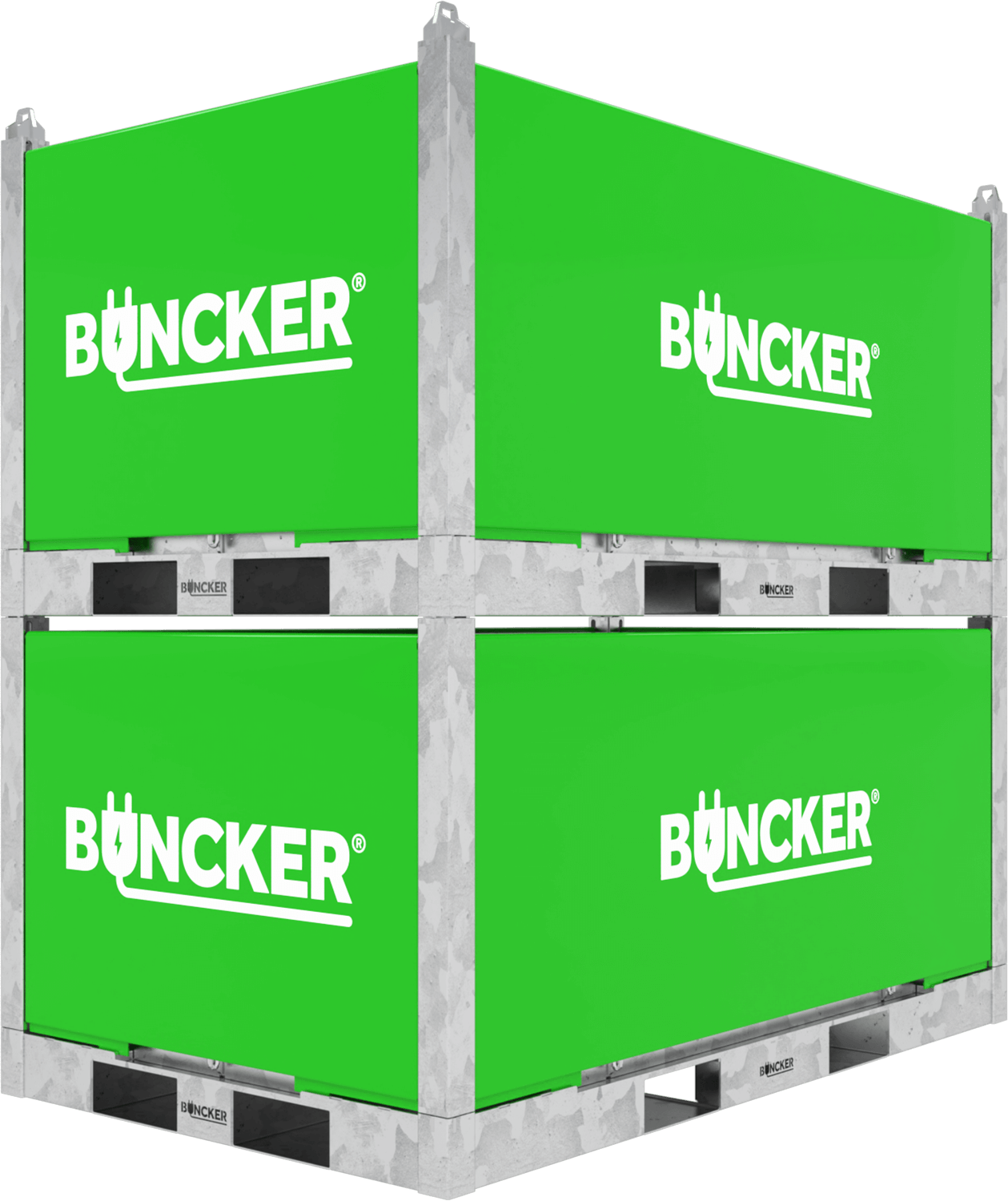

The BUNCKER® Pro Line HEAVY is suitable for the safe transport, storage, and handling of all types of lithium batteries, regardless of whether these lithium batteries are new, instable, suspicious, damaged, defect refurbished, remanufactured or for recycling purposes.

The BUNCKER® Pro Line HEAVY is fully equipped with our patented Fibercon Altilium® CP Blanket (FACB). This innovative product has the potential to filter the toxic HF gasses. In addition, the FACB has non-combustible, fire-resistant and insulating properties.

BUNCKER® packaging is known for its green and sustainable characteristics, as well as its long life cycle, low total cost of ownership, and robustness. Each of these features in more detail:

BUNCKER® packaging is designed with a focus on environmental friendliness. It is made from eco-friendly materials that minimize the impact on the environment. Additionally, BUNCKER® packaging is often designed to be easily recyclable, reducing waste and promoting a circular economy.

BUNCKER® packaging is built to last. It is designed and manufactured with durable materials and construction techniques, ensuring that it can withstand the rigors of transportation, handling, and storage. By having a long-life cycle, BUNCKER® packaging helps minimize the need for frequent replacement and reduces waste generation.

BUNCKER® packaging offers cost advantages over its lifespan. While the initial investment may be higher compared to less durable alternatives, the long-lasting nature of BUNCKER® packaging means that it requires less frequent replacement. BUNCKER® can be operated by 1 person and no inner packaging is needed either. This reduces the overall costs associated with packaging procurement, storage, transportation, handling, waste management and clean-up costs.

BUNCKER® packaging is engineered to be robust and resistant to damage. It is designed to protect the contents effectively during transportation and storage, reducing the risk of product damage or spoilage. The robustness of BUNCKER® packaging contributes to its long-life cycle and overall cost savings.

In a fire emergency, it’s important to prioritize the safety of human lives and property. While water is commonly used as a firefighting tool due to its availability and effectiveness in extinguishing fires, this is an alternative firefighting method that can minimize the impact on the environment.

By combining these attributes, BUNCKER® packaging provides an environmentally conscious solution that meets the needs of businesses while minimizing the ecological impact.

BUNCKER® addresses the lack of awareness and knowledge surrounding the safe handling of lithium batteries. BUNCKER® recognize that regulations can be complex and difficult for users to navigate, and existing solutions may not be user-friendly.

BUNCKER® strives to create solutions that improve safety and simplify the handling of lithium batteries. This includes developing user-friendly instructional materials, safety guidelines, green solutions, or innovative tools and technologies for safe lithium battery management.

BUNCKER® made in Holland benefits from the country’s strong focus on innovation and sustainability. The Netherlands has been at the forefront of sustainable development and has a supportive environment for companies working on innovative solutions.

BUNCKER®, Berlin Packaging Dangerous Goods in co-operation with Lithium Safety Solutions & VDL Staalservice